Final assembly and test milestones on tap for NASA’s first Orion moon ship – Spaceflight Now

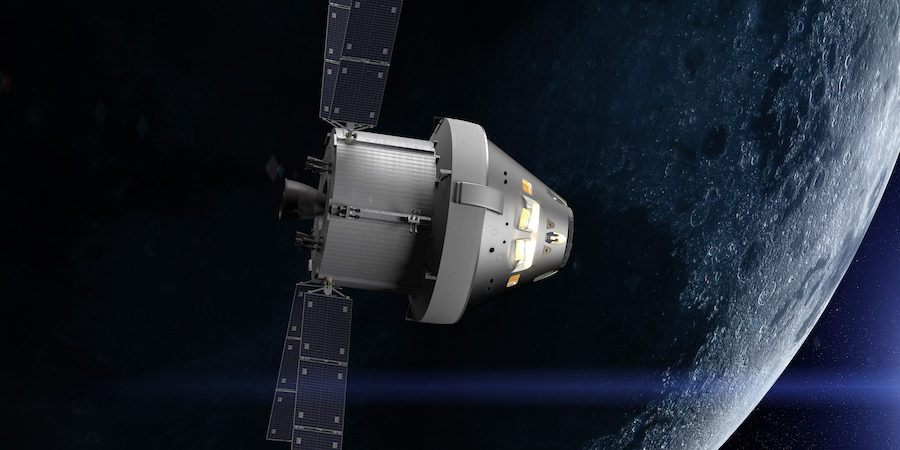

The pressurized crew module and European-built service module for NASA’s first Orion spacecraft to travel to the moon will be joined together for the first time in the coming weeks at the Kennedy Space Center, with preparations — at least for Orion — on a pace to be ready for launch on an unpiloted test flight next year.

The connection will set the stage for shipment of the Orion spacecraft from KSC to NASA’s Plum Brook Station in Ohio, where engineers will test the moon ship’s ability to withstand the rigors of spaceflight. Environmental testing sometimes reveals technical issues on spacecraft, and managers caution that the Orion testing could uncover problems.

Even if it’s not smooth sailing during the upcoming test regimen, the first-ever joining of Orion’s two main elements, built on opposite sides of the Atlantic Ocean, is a major step in preparing the spacecraft for launch on the first deep space mission by a human-rated space capsule since 1972.

The Orion test flight around the moon is the first major mission under NASA’s recently-renamed Artemis program, which aims to land U.S. astronauts on the moon by 2024 as a stepping stone to eventual expeditions to Mars.

“The work we have ongoing in the Operations and Checkout Building with our Artemis 1 vehicles, the next big milestone, which will happen some time toward the end of July, is we’re going to mate the crew module to the service module,” said Mark Kirasich, NASA’s Orion program manager at the Johnson Space Center in Houston. “We’ll have one integrated stack, and we’ll do a series of tests to that vehicle to make sure the crew module and service module function well together.”

“When that series of testing is complete in the fall, some time in September, we put that stack in an airplane and fly it to Sandusky, Ohio, where we have an environmental test chamber.”

Orion’s first test flight around the moon could be ready for liftoff by the end of next year, but NASA is re-evaluating the schedule in the wake of more delays in the construction of the Space Launch System, the heavy-lift rocket designed to loft the capsule on lunar missions.

NASA completed a test of the Orion spacecraft’s escape system July 2, demonstrating that the capsule could quickly fly free of its SLS rocket in the event of an emergency during launch. That was the last flight test for the Orion program before the unpiloted mission to lunar orbit next year, a mission designated as Artemis 1.

“The next big check mark is the moon,” Kirasich said.

Kirasich said July 2 that the Artemis 1 mission could take off “a little over a year from now.”

But that schedule remains nebulous, and although the Orion spacecraft may appear to have a clear path to be ready next year — assuming no major issues are uncovered during testing — development woes with the SLS core stage remain a hurdle.

“We’ll be sending Orion on the Space Launch System rocket, and the destination of that (Artemis 1) mission is the moon,” Kirasich said. “Between now and then, we have a number of qualification tests to complete, a couple of big ones.”

NASA Administrator Jim Bridenstine last week reassigned Bill Gerstenmaier, the longtime head of the agency’s human spaceflight programs, to become a special advisor at NASA Headquarters in Washington. Bridenstine said NASA is searching for a permanent replacement after removing Gerstenmaier from his post.

The management shakeup comes amid a push engineered by the Trump administration to fast-track a human landing on the moon within the next five years.

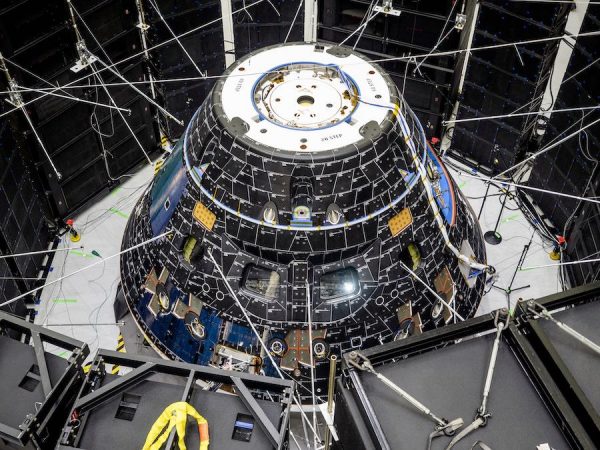

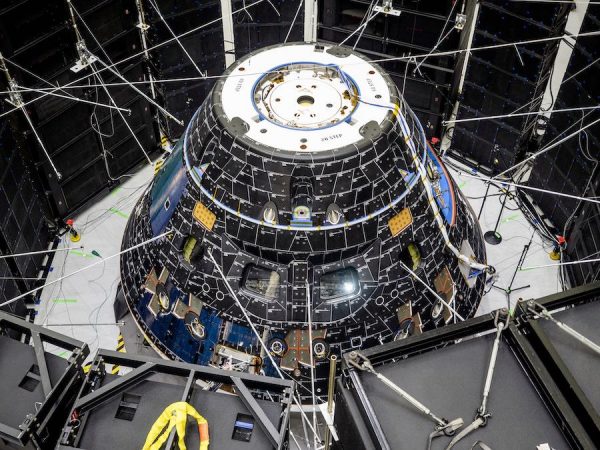

The pressure shell for the Artemis 1 mission’s Orion crew module arrived at the Kennedy Space Center on Feb. 1, 2016, from the Michoud Assembly Facility in New Orleans, where Lockheed Martin technicians completed the initial assembly of the spacecraft.

Since arriving in Florida, workers have installed the spacecraft’s base heat shield, access hatch, parachutes, avionics control boxes, propellant tanks and and 12 rocket thrusters to control the capsule’s orientation during atmospheric re-entry.

“The avionics are in, the propulsion is in, the heat shield is on,” said Mike Hawes, Orion program manager at Lockheed Martin, NASA’s prime contractor for the human-rated spaceship.

Teams working inside the Armstrong Operations and Checkout Building at KSC completed weight and center-of-gravity measurements on the Orion crew module at the end of June.

“The crew module is almost there,” Hawes said.

Meanwhile, engineers from Airbus Defense and Space, which built the Orion service module in Germany, are in the final stages of readying that unit for attachment with the crew module.

“On the service module, there were a couple of boxes for the solar array drives that had to get sent back to Europe,” Hawes said. “They found a discrepancy in a (ground) box, and they had to check the flight boxes to be sure. So they’ve done that repair, reloaded the software.”

The European Space Agency and NASA announced an agreement in 2013 for Europe to provide the Orion service module for the spacecraft’s first unpiloted test flight around the moon, the mission now named Artemis 1. At the time, ESA agreed to provide parts for the Orion service module for the ship’s first mission with a crew, then known as Exploration Mission-2 and since renamed Artemis 2.

Since 2013, ESA has agreed to build two full service modules for the Artemis 1 and 2 missions, and the space agency launched procurement for a third Orion service module with Airbus last year. ESA officials have expressed interest in providing additional service modules well into the 2020s.

The service modules provide propulsion, propellants, electricity, water, oxygen, nitrogen and thermal control for the Orion spacecraft.

The service module has 33 engines and thrusters to control the Orion capsule’s orientation and adjust its trajectory after launch. The main engine for Artemis is a refurbished Orbital Maneuvering System engine that flew on the space shuttle.

The OMS engines were mounted on pods on each side of the shuttle’s vertical tail, used to change the craft’s orbit and begin the spaceship’s trip back to Earth with a deorbit burn.

The engines burn hydrazine and nitrogen tetroxide propellants, and were each designed for 100 missions and rated for multiple restarts on each flight.

Aerojet Rocketdyne built the OMS engines, which provide around 6,000 pounds of thrust in vacuum.

The service module arrived at KSC from Germany last November, and teams in Florida have since mated the service module with Orion’s crew module adapter, the structure that will connect the spacecraft’s two main pieces. Teams also brought in huge arrays of speakers to blast the crew module and service module with sound, testing their resilience to the acoustics of launch.

NASA and industry teams at KSC previously planned to mate the Orion modules in June, but engineers continued with troubleshooting and testing on the service module’s helium pressurization system, which is used to prime the spaceship’s thrusters for use, Hawes said.

Valves inside the propulsion system has been one of the most challenging parts of the service module’s development. On the crew module side, one component requiring extra focus has been the side hatch. NASA originally intended to fly a makeshift metal covering over the hatch opening on the Artemis 1 mission, but later decided to fly the full hatch design.

Once teams deem the pressurization system ready, workers were expected to transfer the service module into the Final Assembly and System Testing cell inside the Operations and Checkout Building, the same facility once used to integrate NASA’s Apollo moon ships.

With the two Orion segments physically connected, all that’s left is powering up the full vehicle, conducting a fully-integrated systems test, final installation of closeout and backshell panels, and putting payloads, cameras and instrumented dummies inside the pressurized crew module to collect data on the environment inside the spacecraft for astronauts.

NASA’s Super Guppy cargo plane will ferry the Orion spacecraft to Ohio for testing inside a huge chamber built to expose the vehicle to the super-cold airless conditions of deep space. Engineers will also conduct an electromagnetic interference and compatibility test with the Orion spacecraft before shipping it via air back to Florida.

By next spring, the Orion spacecraft should be back at KSC and ready for handover to the ground operations team, which will affix the abort system on top of the capsule, fill the spaceship with propellants, and ready Orion for stacking on top of the Space Launch System inside the Vehicle Assembly Building.

But even if Orion is ready, the SLS may still be lagging.

“We need a rocket,” Hawes said. “We come back (from Ohio), the (ground systems) folks fuel the vehicle, they’ll mount the launch abort system on top, and then it’s turned over and ready to be integrated with the launch vehicle.”

A basic version of the Orion crew module flew in Earth orbit in December 2014 after lifting off on top of a United Launch Alliance Delta 4-Heavy rocket. But that test flight, known as Exploration Flight Test-1, did not include many crew module systems, or a functioning service module.

NASA and Lockheed Martin last year finished a series of drop tests from airplanes to verify the Orion spacecraft’s parachutes will function during return to Earth. Three main parachutes will slow the capsule down for splashdown at sea, where a U.S. Navy vessel will recover the spacecraft.

Managers plan more ground testing of the Orion launch abort system in the coming months, and structural and avionics qualification testing on an engineering model of the Orion spacecraft is underway at a Lockheed Martin facility in Denver. In New Mexico, engineers are working on a full-scale qualification test of the service module’s propulsion system, Kirasich said.

Meanwhile, the build-up of the crew module and service module for the piloted Artemis 2 mission continues in Florida and in Germany. NASA says Artemis 2 could take off in 2022 or 2023 and carry astronauts around the moon and back to Earth

Since its start under the George W. Bush administration, the Orion program has cost NASA about $16 billion. The Orion spacecraft has survived two major upheavals in NASA’s human spaceflight brought on by shifts in space policy goals by the Obama and Trump administrations.

Now NASA leaders consider Orion a crucial component of the agency’s push to put humans back on the lunar surface by 2024, a charge announced by Vice President Mike Pence in March. Bridenstine, the head of NASA, named the accelerated moon landing program Artemis, the twin sister of Apollo in Greek mythology.

The Artemis 1 mission will be a shakedown cruise for the Orion spacecraft in lunar orbit, setting the stage for a crewed mission on Artemis 2, and potentially a lunar landing attempt on the Artemis 3 mission in 2024.

But Bridenstine has said that schedule could require the addition of $20 billion or more to NASA’s budget over the next five years, with much of the funding going toward development of a human-rated lunar lander, which does not exist today.

Bridenstine said Monday that expanding NASA’s partnerships with commercial industry could lower the government’s extra financial burden, perhaps to less than the $20 billion figure he previously mentioned. But lawmakers have not yet approved the Trump administration’s request for $1.6 billion of additional NASA funding next fiscal year.

That $1.6 billion request is only a down payment on the fast-track, five-year moon landing program.

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.