First SLS core stage departs factory – Spaceflight Now

The heart of NASA’s first flight-ready Space Launch System heavy-lift rocket emerged from its factory in New Orleans Wednesday morning for a barge trip to the Stennis Space Center in Mississippi for an eight-minute test-firing of its space shuttle-era hydrogen-fueled engines.

The 212-foot-long (64.6-meter), 27.6-foot-wide (8.4-meter) core stage of the Space Launch System rolled out of its factory at the Michoud Assembly Facility, signaling a significant, but long-delayed milestone in the SLS program’s eight-year history.

Teams loaded the core stage into NASA’s Pegasus barge to be ferried on a half-day journey to the Stennis Space Center in Mississippi.

Spaceflight Now was at Michoud for Wednesday’s rollout ceremony, which occurred with festive New Orleans flair. Some SLS team members wore shiny bead necklaces, and a “second line” New Orleans drum and brass band accompanied the rocket on the trek out of the factory.

With a bit of New Orleans flair, the core stage for NASA’s first Space Launch System heavy-lift rocket rolled out of its factory Wednesday morning to head for the Stennis Space Center in Mississippi for a test-firing later this year. PHOTO GALLERY: https://t.co/5LcG2UzkVa pic.twitter.com/GnjgoJJHRS

— Spaceflight Now (@SpaceflightNow) January 9, 2020

Built by Boeing, the core stage is covered in insulating foam, similar to the thermal insulation used on the space shuttle’s external tank. The core stage has the same diameter as the shuttle fuel tank and was built in the same factory in east New Orleans.

The huge first stage of NASA’s Saturn 5 moon rocket was also manufactured at Michoud.

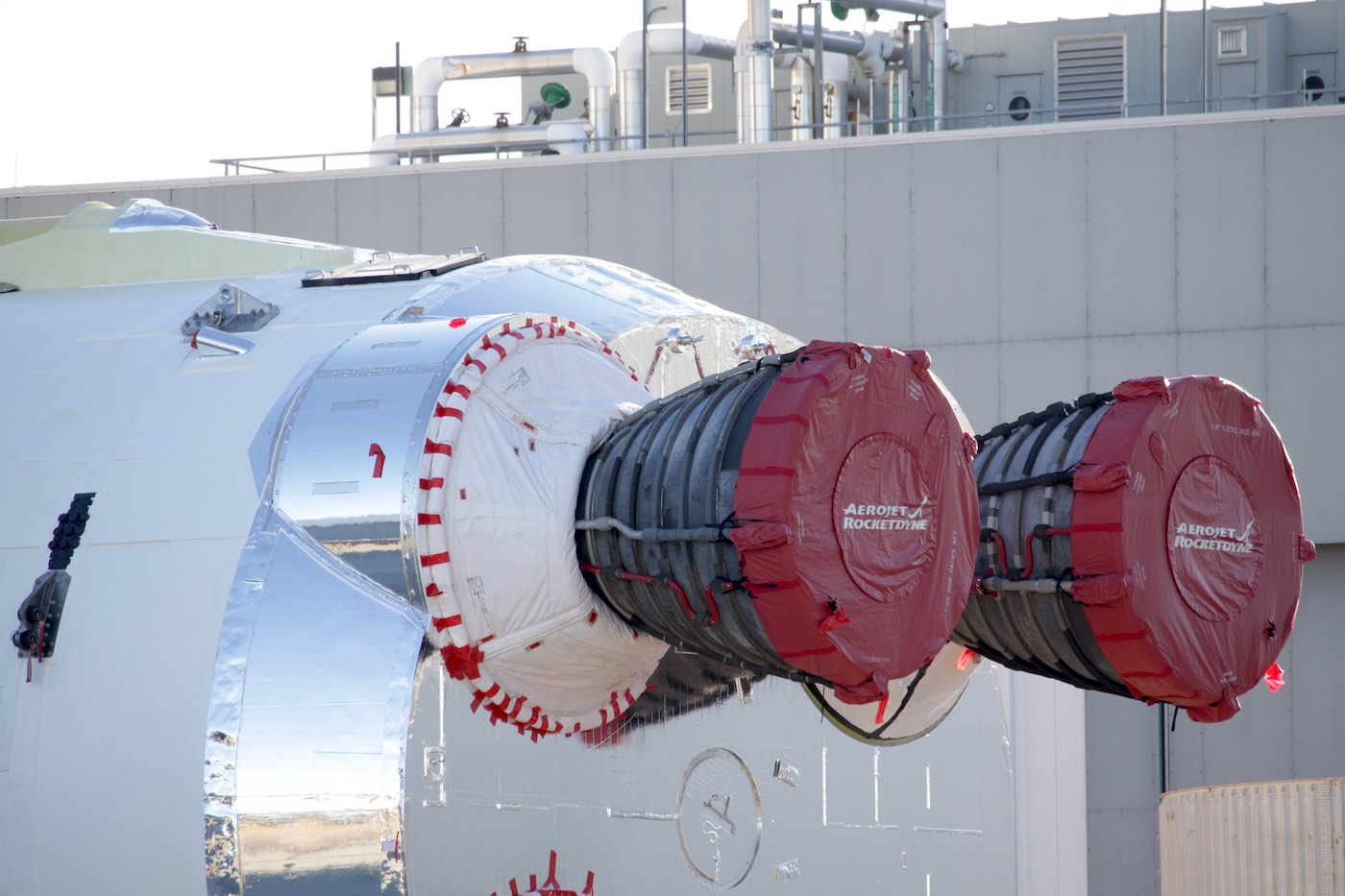

Another piece of technology borrowed from the space shuttle for the SLS core stage is its use of RS-25 main engines. Four Aerojet Rocketdyne-built RS-25 engines, each a veteran of multiple space shuttle launches, are affixed to the chrome-colored aft end of the SLS core stage.

Those four engines are upgraded with modernized electronics and rated for slightly higher throttle settings than they were in the shuttle program. The RS-25 engines will be ignited later this year on a test stand at the Stennis Space Center in southern Mississippi during a “green run” test series designed to confirm the rocket works as designed when loaded with more than 700,000 gallons of super-cold liquid hydrogen and liquid oxygen propellants.

The four RS-25 engines will power up to full throttle to generate nearly 2 million pounds of thrust during the hotfire test.

Once the green run test is complete in Mississippi, NASA will ship the core stage to the Kennedy Space Center in Florida, where it will join two side-mounted solid-fueled boosters — also using modified space shuttle technology — and an upper stage derived from United Launch Alliance’s Delta 4-Heavy rocket.

The SLS will blast off from pad 39B at the Florida spaceport some time in 2021. A target launch date is still under review after a series of delays have pushed back the SLS’s inaugural test flight from its original schedule in 2017.

The first launch, designated Artemis 1, will carry NASA’s Orion crew capsule on an unpiloted flight into lunar orbit and back to Earth. Boeing teams at Michoud are building a second SLS core stage for the Artemis 2 mission, which could blast off in 2022 or 2023 to carry another Orion vehicle with four astronauts around the moon and back.

The Artemis program’s third mission, planned for 2024, could include an attempt to land astronauts on the moon, a five-year goal set by the Trump administration last year.

Read our earlier story for the details on completion of manufacturing on the SLS core stage.

More photos from Wednesday’s rollout of the SLS core stage in Louisiana are posted below.

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.