Mars 2020 rover on track for launch next July – Spaceflight Now

The launch of NASA’s Mars 2020 rover is less than a year away, and the steady pace of work inside the craft’s pristine assembly hall in California is keeping the mission on schedule for liftoff from Cape Canaveral next July, despite growing costs, according to mission managers.

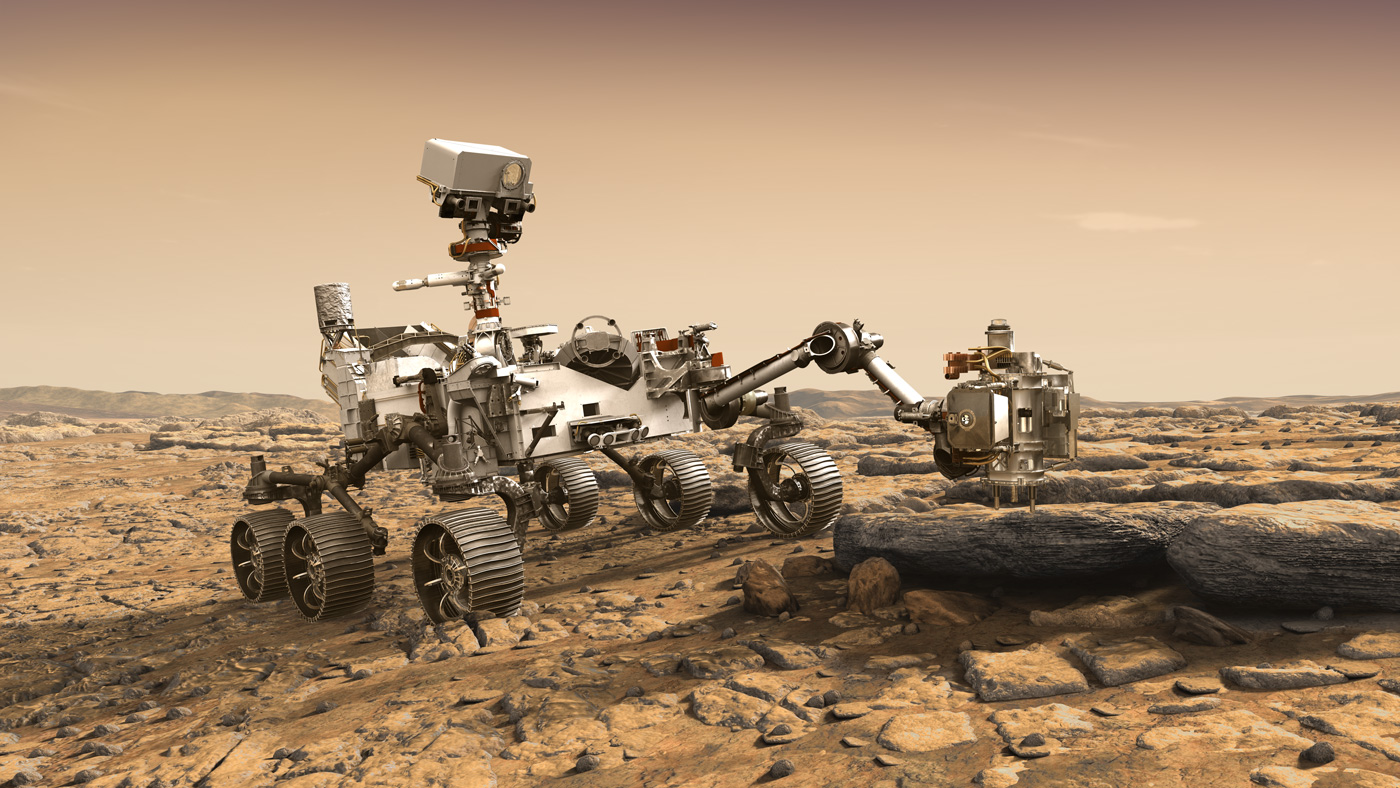

Based on the Curiosity rover currently exploring Mars, the Mars 2020 rover will weigh more than a ton when it heads for the Red Planet next year. Engineers at NASA’s Jet Propulsion Laboratory will install the final components inside the robot in the next few weeks. Once completed, the rover will go through a series of functional and environmental tests to ensure it is ready for Mars.

The plutonium-powered rover is scheduled for lift off July 17, 2020, from Cape Canaveral on top of a United Launch Alliance Atlas 5 rocket. While teams assemble the rover at JPL, engineers are also finalizing work on the mission’s cruise and descent stages, which will protect the rover on its flight from Earth and through the Martian atmosphere for landing Feb. 21, 2021.

Aside from a ceremonial team photo, Mars 2020 scientists and engineers treated this year’s July 17 — marking one year before launch — like a regular work day, assuming one’s job involves building an interplanetary robot.

“We are getting very, very close (to finishing the rover),” said Matt Wallace, the Mars 2020 mission’s deputy project manager at JPL. “I would say we are over 95 percent there, maybe even 98. We really just have a handful of things left.”

“We’re less than a year from launch, and we’re just a handful of months from starting to deliver hardware to the Cape,” said Jim Watzin, director of NASA’s Mars exploration program, in a July 26 meeting of the Mars Exploration Program Analysis Group.

In June, workers inside the Spacecraft Assembly Facility at JPL installed the Mars 2020 rover’s remote sensing mast, six wheels and the 7-foot-long (2.1-meter) robotic arm. Crews at JPL also added the rover’s scientific instruments to the vehicle, many of which are directly mounted to the remote sensing mast, which will raise up to a height of more than 7 feet (2.2 meters) after landing on Mars, or to the end of the robot arm.

The engineering work on the Mars 2020 rover has been hastened by JPL’s experience building the Curiosity rover.

But the new rover features different instruments to search for signs of ancient microbial life on Mars, adding fresh capabilities to the toolkit built for Curiosity. The Mars 2020 rover also carries an untried set of internal mechanisms to collect, store and seal rock core samples for return to Earth on a future mission, a new wheel design to avoid problems that plagued Curiosity, and a major upgrade known as terrain relative navigation to steer the rover’s descent stage away from boulders, craters and other obstacles upon landing.

The science instruments and Sample Caching System proved to be the most difficult part of developing the Mars 2020 mission, but there’s light at the end of the tunnel.

“All the instruments are on. All of them are there,” Wallace said in a recent interview with Spaceflight Now.

One of the final major instrument deliveries to the JPL clean room was SuperCam, an intricate suite of sensors, including a camera, laser and spectrometers, designed to zap Martian rocks from more than 20 feet (6 meters) away to measure their chemical and mineral make-up, with the ability to identify organic molecules.

Developed by an international team in the United States, France and Spain, the SuperCam instrument is an upgraded version of the ChemCam instrument currently operating on NASA’s Curiosity rover, which arrived at Mars in 2012.

SuperCam is fixed to the top of the Mars 2020 rover’s remote sensing mast, alongside the first zoom-capable camera to fly to the Red Planet. Martian weather sensors provided by Spain are also mounted to the mast.

“On SuperCam, the French partners really came through in a big way and held schedule for the last six months, just working night and day to get it done,” Wallace said. “The last couple of instruments out on the end of the arm — PIXL and SHERLOC — those were delivered in the last couple of weeks, and that finished off the surface (science) instruments.”

PIXL stands for the Planetary Instrument for X-ray Lithochemistry. It will measure the chemical elements present in Martian rocks and soils. The Scanning Habitable Environments with Raman and Luminescence for Organics and Chemicals, or SHERLOC, instrument carries an ultraviolet laser and spectrometer to detect organic materials and minerals on the surface of Mars, along with an accompanying context camera.

SHERLOC survived a termination review earlier this year after teams experienced technical difficulties with the instrument, driving up its cost. The SHERLOC team resolved an issue with a high-voltage power supply and delivered the instrument for integration with the rover earlier this month.

Engineers putting together the rover at JPL installed the robot arm’s turret July 11. The turret is an 88-pound (40-kilogram) package containing the PIXL and SHERLOC instruments, along with cameras, which the arm can place against Martian rocks to obtain fine-scale measurements.

The turret also holds a percussive drill and coring mechanism to collect rock samples for eventual return to Earth.

The Mars 2020 team activated the robotic arm for a motion test July 19.

“This was our first opportunity to watch the arm and turret move in concert with each other, making sure that everything worked as advertised — nothing blocking or otherwise hindering smooth operation of the system,” said Dave Levine, integration engineer for Mars 2020. “Standing there, watching the arm and turret go through their motions, you can’t help but marvel that the rover will be in space in less than a year from now and performing these exact movements on Mars in less than two.”

There are two other instruments on the Mars 2020 rover. The MOXIE payload will demonstrate the production of oxygen from carbon dioxide in the atmosphere of Mars, and a Norwegian-developed ground-penetrating radar will study the Red Planet’s underground geologic structure.

“That last year or 18 months leading up to system integration are probably the most stressful and trying times of a project, and it’s no exception for Mars 2020,” Watzin said. “They have a lot challenging payloads that go on that rover, and as they work their way though performance testing and environmental testing, no surprise, we discovered some issues that had to be addressed, and we’ve had to iterate and repeat.”

Space enthusiasts can watch a live video feed from inside the Mars 2020 clean room at JPL, showing workers as they build up the rover, which spans about 10 feet (3 meters) long, 9 feet (2.7 meters) wide, and 7 feet (2.2 meters) tall.

One of the last major items to be added to the rover is a package of sophisticated instrumentation designed to sort, transfer and store rock samples for retrieval by a future robotic Mars mission that will return the specimens to Earth.

The Sample Caching System is a complicated piece of equipment, with 17 separate motors, a rotating wheel containing nine drill bits, and 43 tubes to hermetically seal core samples drilled from Martian rocks.

“The most substantial thing (left to install) is what we call the caching system,” Wallace said. “There’s a set of mechanisms that sit just inside the front of the vehicle. They’re not externally visible, but when we take the sample using the drill out of the end of the robot arm, we transfer it back to the through something call a bit carousel on the front of the vehicle, and into the internal mechanisms and the caching assembly and the tubes get inspected, sealed and stored in there.”

The portion of the caching system inside the rover is called the Adaptive Caching Assembly, which consists of more than 3,000 parts alone.

“There’s a small robot arm in there, which does the manipulation, and hardware that does the sealing and inspection (of the tubes) and those sorts of things,” Wallace said. “That’s really the most substantial thing left.”

The caching tubes themselves, each sterilized with extreme heat in an oven, will be installed on the rover at the Kennedy Space Center in Florida next year. Managers want to minimize the exposure of the tubes to contamination before launch to help ensure the specimens are pristine when they come back to Earth.

After collecting the core samples, the Mars 2020 rover will drop some of the tubes at “depots” on Mars for pick-up by a future mission, which will include a lander and rocket to lift the samples back into space for return to Earth.

Teams at JPL will also attach the Mars Helicopter — the first vehicle built to fly through the atmosphere of another planet — to the belly of the Mars 2020 rover in the coming days.

“And the helicopter,” Wallace added. “The helicopter will be going on (soon). It sits up underneath the vehicle. That’ll be it.”

Then engineers will prepare for a series of tests in the autumn, beginning with a vibration test with the rover attached to its sky crane descent stage, the same type of landing vehicle that delivered the Curiosity rover to Mars.

“We are advancing on all fronts — including completion of the cruise stage that will guide us to Mars and the sky crane descent landing system that will gently lower us to the surface,” said John McNamee, the Mars 2020 project manager at JPL. “And the rover is not only looking more and more like a rover each day, it’s acting like one.”

The rover will then be detached from its descent stage to go through a thermal vacuum test, a check of the vehicle’s resilience to the cold temperatures and low atmospheric pressure on Mars. A test of the rover’s electromagnetic properties is also planned, according to Wallace.

The Mars 2020 cruise stage is scheduled to ship to the Kennedy Space Center in Florida in December, followed by the cross-country air cargo flight of the rover and descent stage from California to Florida in February.

Wallace said the heat shield that will protect the rover as it plunges into the Martian atmosphere should be ready for transport from a Lockheed Martin facility in Colorado to KSC by the end of the year, too.

Lockheed Martin built a new heat shield for Mars 2020 after the structure originally intended for the mission — a spare left over from the development of Curiosity — cracked during ground testing last year.

NASA reported earlier this year that the total cost of the Mars 2020 mission, which is designed to operate on Mars for two Earth years, was expected to exceed the agency’s previous budget commitment of $2.4 billion. But Watzin said July 26 that the Mars 2020 has “adequate schedule reserves” to deliver hardware to the launch site on time.

After stacking the rover, descent stage and cruise stage, ground teams will hoist the entire spacecraft on top a ULA Atlas 5 rocket and connect the rover’s nuclear power source ahead of the opening of the mission’s 20-day primary launch period.

Earlier this month, NASA authorized the fueling of Mars 2020’s nuclear power generator with plutonium-238.

Launches directly from Earth to Mars are possible every 26 months, and next year’s launch opportunities begin July 17.

Based on the latest trajectory analysis, the launch window July 17 will open at 1300 GMT (9 a.m. EDT), with daily windows of between one and two hours available each day through Aug. 5. Mars 2020 will fly on the same variant of the Atlas 5 — with four solid rocket boosters — that launched the Curiosity rover in 2011.

NASA plans to oversee a naming competition beginning this fall to give U.S. primary and secondary school students a chance to select a name for the Mars 2020 rover.

The mission will target a landing in Jezero Crater, home to an ancient river delta and lake that scientists believe filled the crater some 3.5 billion to 3.9 billion years ago.

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.