A new thrust technology for nanosatellites could make them more efficient – MIT Technology Review

Back in 1964, the Soviet Union launched a spacecraft called Zond 2 toward Mars. Its mission was to orbit the Red Planet, photograph the surface, look for signs of methane in the atmosphere, and release a craft to land on the surface.

But several months after launch, Zond 2’s troublesome power supply failed. The Soviets lost contact with the craft and never heard from it again. Today the mission is largely thought of as a failure—one of many where Mars is concerned.

But Zond 2 had another goal. The spacecraft was fitted with six revolutionary thrusters for attitude control. Known as plasma jet engines, these devices had never been used in space. But during various tests after launch, Zond 2 proved they could work.

Since then various spacecraft have relied on this form of propulsion (and on a slightly different form using ion thrusters). These engines have significant advantages over conventional chemical rockets because they are simpler, lighter, and more efficient.

They are also significantly smaller than chemical thrusters. That makes them useful for the makers of nanosatellites—the increasingly common spacecraft with a mass less than 10 kilograms, which are often little bigger than a Rubik’s cube.

But plasma thrust engines are not perfect. Turning the onboard propellant into plasma and controlling its flow can be a tricky business that wastes energy and sometimes even damages the engine itself. So finding ways to improve plasma thrust engines is of considerable interest for small-satellite makers.

Enter Adam Patel and colleagues from Purdue University in West Lafayette, Indiana. These guys have come up with a new design for a plasma thruster just as small as its predecessors that has the potential to be even more reliable and efficient.

First, some background about the propellant that plasma thrusters rely on. Most use a solid propellant such as polytetrafluoroethylene, otherwise known as Teflon. That’s easy to store, but to be used, it must be vaporized by passing a current through the surface.

The vapor is then ignited, creating a “flashover” that turns it into a plasma. The plasma then passes through an electromagnetic field, where it experiences an accelerating force that propels the spacecraft in the opposite direction.

The problem is that this ablation is a hit-and-miss process. The rate is difficult to control, and this can make the thrust non-uniform. Also, the Teflon surface sometimes breaks down and ejects debris in the form of macroparticles that interfere with the engine operation.

What’s more, the igniter that triggers the flashover process can become damaged over time. All these problems ultimately limit the efficiency of the solid-fuel plasma thrusters to less than 15%.

One way around this is to store the propellant as a gas and control its release with a gas injection system. This increases the efficiency of the engine by up to 70%. But these systems are bulky and complex, and the gas itself has a significantly larger volume than an equivalent solid mass. That makes it hard to build into a nanosat.

Now Patel and co say they can fix these problems using a liquid propellant. “A liquid-fed pulsed plasma thruster could potentially overcome several disadvantages associated with traditional pulsed plasma thruster devices,” they say.

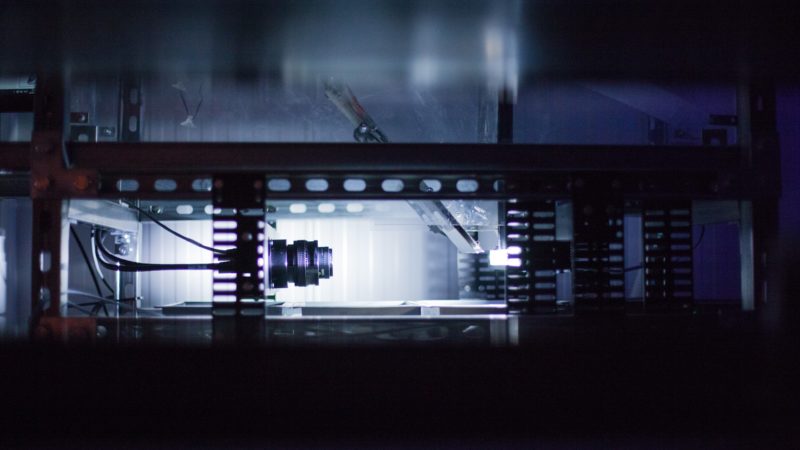

Indeed, they’ve built a proof-of-principle micro-propulsion system fed by liquid and put it through its paces in a vacuum chamber. As a propellant, they use pentaphenyl trimethyl trisiloxane (C33H34O2Si3), a viscous liquid with low vapor pressure that is also an excellent dielectric.

The team also designed a new low-energy ignition system. This consists of two plate electrodes separated by a dielectric. It works by increasing the voltage across the plates to a threshold value at which the dielectric vaporizes and becomes plasma.

In this case, the dielectric is the liquid propellant. The plasma then enters the electromagnetic fields, where it accelerates.

The advantage of this kind of igniter is that the threshold voltage is always the same, and so the amount of energy required for flashover is always limited. This limits the potential damage to the flashover assembly over time.

In tests, Patel and co used the igniter for upwards of 1.5 million flashover events without observing any significant damage to the device. Other designs can sometimes fail after only 400 firing cycles.

Patel and co went on to measure the plasma exhaust velocity at 32 kilometers per second. This allowed them to calculate that the engine produces a respectable thrust of up to 5.8 newtons.

That’s a solid first step toward better micropropulsion systems for nanosatellites.

However, there is more development work ahead. One important task will be to design and build a simple liquid feed system that operates reliably in zero gravity. In these experiments, the researchers injected the liquid into the igniter by hand using a syringe.

It’s not hard to imagine how that could be automated, but liquids are notoriously difficult to control in zero G. So Patel and co will have their work cut out in developing a simple system that satellite makers can rely on. But therein lies another tale.

Patel and co certainly have bigger ambitions or their device. “The results of this paper provide valuable information to enable the development of a flight-ready liquid fuelled pulsed plasma thruster,” they say. It’ll be interesting to see how they do it.

Ref: arxiv.org/abs/1907.00169 : Liquid-Fed Pulsed Plasma Thruster for Propelling Nanosatellites