Space station receives spacewalking gear, new baking oven – Spaceflight Now

NASA astronaut Jessica Meir took control of the International Space Station’s Canadian-built robot arm Monday to capture a Northrop Grumman Cygnus supply ship carrying crew provisions, spacewalking gear to repair an aging particle physics experiment, tech demo satellites for the U.S. military, and an oven to bake the first cookies in space.

The automated cargo freighter arrived at the space station Monday, using GPS and laser-guided navigation to fine-tune its rendezvous along an approach corridor below the research complex. The Cygnus spacecraft held its position less than 40 feet, or about 12 meters, below the station for Meir to command the robotic arm to capture the supply ship at 4:10 a.m. EST (0910 GMT) Monday.

Engineers in mission control were expected to take over commanding of the robot arm to berth the Cygnus spacecraft to the station’s Unity module a few hours later, setting the stage for astronauts to open hatches leading to the pressurized cargo carrier to begin unpacking the supplies inside.

The Cygnus spacecraft launched Saturday atop an Antares rocket from Wallops Island, Virginia, with approximately 8,168 pounds (3,705 kilograms) of food, experiments, hardware, and small satellites set for deployment in orbit in the coming months.

Here’s a breakdown of the cargo manifest provided by NASA:

- 4,372 pounds (1,983 kilograms) of science investigations

- 1,667 pounds (756 kilograms) of vehicle hardware

- 1,499 pounds (680 kilograms) of crew supplies

- 262 pounds (119 kilograms) of unpressurized cargo (NanoRacks CubeSat deployer)

- 229 pounds (104 kilograms) of spacewalk equipment

- 77 pounds (35 kilograms) of Northrop Grumman hardware

- 37 pounds (17 kilograms) of computer resources

- 24 pounds (11 kilograms) of Russian hardware

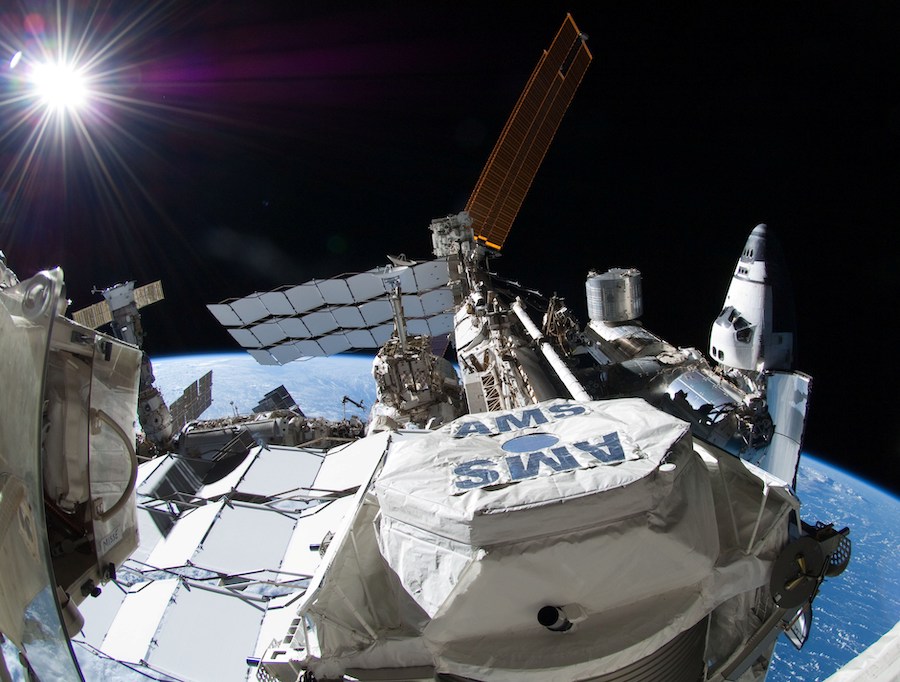

The equipment inside the Cygnus cargo freighter’s Italian-made pressurized compartment include tools and replacement hardware for an upcoming repair of the Alpha Magnetic Spectrometer.

European Space Agency astronaut Luca Parmitano and NASA flight engineer Andrew Morgan will perform the spacewalks to repair the AMS instrument, which was not designed to be serviced in space. The complicated repairs are expected to require four or five spacewalks to complete, beginning in mid-November.

Mounted on the space station’s truss on the final mission of the space shuttle Endeavour in 2011, the Alpha Magnetic Spectrometer is effectively a powerful magnet that attracts cosmic rays, subatomic particles traveling through space at nearly the speed of light.

Three of the four coolant pumps on AMS’s silicon tracker, which measures the trajectory and energy of the cosmic rays captured by the instrument, have failed, prompting NASA engineers to develop a plan to repair the coolant system. The work required the development of special tools to cut into the AMS instrument, install new hardware, and re-seal tiny coolant lines.

The Alpha Magnetic Spectrometer was never designed to be serviced in space. Read our earlier story for details on the repairs.

There were 15 small satellites riding aboard the Cygnus spacecraft for Saturday’s launch.

The biggest of the group is a U.S. Air Force satellite named STPSat 4, which weighs roughly 220 pounds (100 kilograms) and will be transferred into the space station’s Kibo module by astronauts the Cygnus hatch is opened. Sponsored by the military’s Space Test Program, STPSat 4 will be one of the largest satellites ever deployed from the space station.

STPSat 4 carries five experiments from the Air Force Research Laboratory, the U.S. Air Force Academy, and the U.S. Navy. The experiments will test radio frequency module tiles, help develop new solar array technology, collect data with a miniaturized space weather instrument, demonstrate the performance of an advanced U.S.-built star tracker, and assist in nanosatellite tracking.

Craig Technologies, based on Florida’s Space Coast, is providing integration services for the STPSat 4 spacecraft, which will be released from the Space Station Integrated Kinetic Launcher for Orbital Payload Systems, or SSIKLOPS, deployer. The mechanism, which was first used in 2014, is designed to release small satellites with masses between 100 and 200 pounds.

The other CubeSats on-board the NG-12 mission are sponsored by NASA, the Air Force, and the National Reconnaissance Office. NanoRacks, a Houston-based space services company, arranged the launch of most of the CubeSats.

Some will be ejected from the space station after the Cygnus spacecraft’s arrival, and others will be released from the Cygnus itself after the cargo vehicle departs the station in January.

Other payloads aboard the Cygnus supply ship include a rodent research experiment. Scientists loaded mice into the spacecraft to investigate how the animals respond to changes in their “circatidal” clock in microgravity.

The 12-hour circatidal clock, in which animals experience equal amounts of light and dark phases each day, is associated with maintaining stress responsive pathways. Scientists want to know if exposure to microgravity changes the animals’ circadian rhythm.

Recent research shows that genes associated with the 12-hour clock are linked with the most common form of human liver disease. The rodent research experiment on the space station could reveal new insights into liver disease, and give scientists ideas for new pharmaceutical treatments, according to NASA.

The Cygnus also carries an experimental garment that astronauts could use to protect themselves from harmful radiation on future deep space missions to the moon and Mars, outside the natural shielding of Earth’s magnetic field.

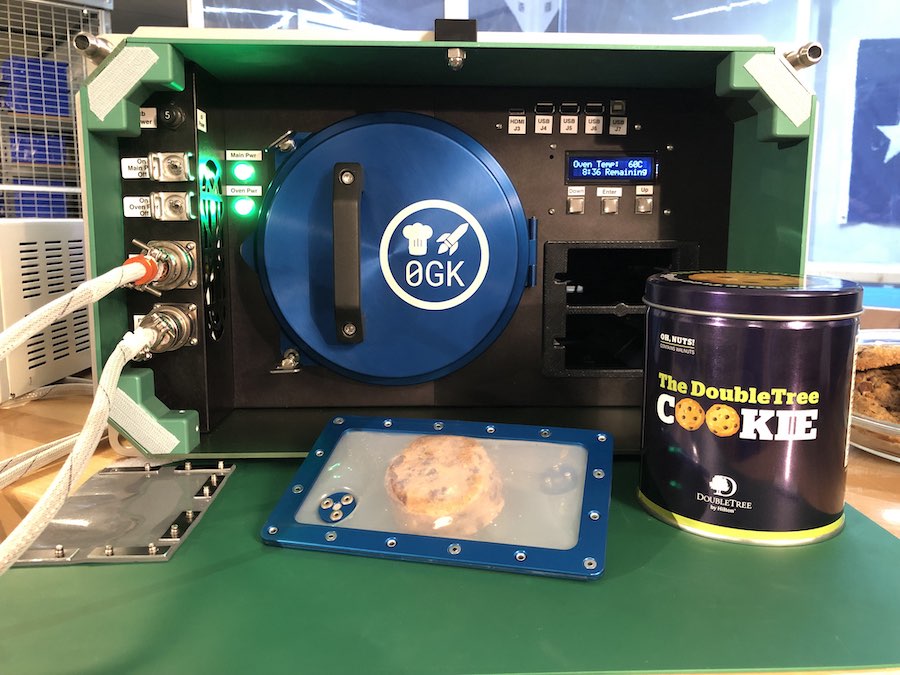

The Cygnus also delivered an oven to the space station designed to bake cookies in microgravity, demonstrating technology that will help future crews cook their own food on lengthy expeditions to the moon or Mars.

But an oven in microgravity doesn’t work the same as one on Earth. The heating elements on the Zero-G Oven, developed by Zero G Kitchen and Nanoracks, are arranged around the oven to focus heat in the center, similar to the way a toaster oven works.

“Currently, on the International Space Station, there is rally a limited ability to prepare foods in ways that we’re used to,” said Ian Fichtenbaum, founder and co-chef of Zero G Kitchen.

Astronauts will load cookies into the oven on a special tray designed to keep the food from floating away in microgravity. Temperatures inside the oven will reach up to 350 degrees Fahrenheit (177 degrees Celsius) during baking, according to NASA.

“Baking in space is different because there’s no gravity,” Fichtenbaum said. “On earth, that air is churning around in the oven, and that’s convection. In space, that is not happening. Instead, we have to use conduction through the oven, conduction through the air, to warm it up.”

The first cookie to be baked in space comes from DoubleTree by Hilton, which provided chocolate chip cookie dough for the baking experiment.

“Science is awesome, food is awesome, and this is just going to be an amazing journey to see what comes out of this,” said Jordana Fichtenbaum, founder and co-chef of Zero G Kitchen.

The Cygnus spacecraft also delivered mice to the space station to investigate how the animals respond to changes in their “circatidal” clock in microgravity.

The 12-hour circatidal clock, in which animals experience equal amounts of light and dark phases each day, is associated with maintaining stress responsive pathways. Scientists want to know if exposure to microgravity changes the animals’ circadian rhythm.

Recent research shows that genes associated with the 12-hour clock are linked with the most common form of human liver disease. The rodent research experiment on the space station could reveal new insights into liver disease, and give scientists ideas for new pharmaceutical treatments, according to NASA.

The Cygnus also carries an experimental garment that astronauts could use to protect themselves from harmful radiation on future deep space missions to the moon and Mars, outside the natural shielding of Earth’s magnetic field.

The AstroRad Vest could shield astronauts from radiation from unpredictable solar storms, which can deliver enough radiation in a few hours to cause serious health problems for space fliers, officials said.

“Our innovation was selective shielding, so we’re selectively shielding those organs that are most prone to either acute radiation syndrome or a cancer down the road,” said Oren Milstein, co-founder and chief scientific officer for StemRad, an Israeli company that originally developed the vest garment to protect first responders from radiation during a nuclear accident.

StemRad is partnering with Lockheed Martin, the prime contractor for NASA’s Orion crew capsule, to transfer the vest technology to space.

Astronauts on the International Space Station will wear the vest to check its comfort and function, according to Kathleen Coderre, the AstroRad Vest’s principal investigator from Lockheed Martin.

The vest weighs nearly 50 pounds (about 22 kilograms). Milstein said the garment is made of dense polyethylene embedded in a highly flexible textile mesh.

“It is an ergonomic experiment, so the vest needs to protect the crew from the deep space radiation environment, but it also needs to be comfortable to wear, flexible enough for them to do their daily duties,” Coderre said.

A similar vest will fly on the Orion crew module on the Artemis 1 mission, an unpiloted test flight into orbit around the moon that will verify the spacecraft’s readiness to carry astronaut. That experiment will test the vest’s protective capability in the deep space radiation environment, which is more harsh than the radiation present at the International Space Station in low Earth orbit.

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.