Space, Right Here At Home In SoCal – Forbes

Being housebound during the Coronavirus outbreak, had me thinking about an exciting space story close to home. I am blessed to teach entrepreneurship in the very heart of the global commercial space industry, Southern California. SpaceX, Virgin Orbit, Rocket Lab, Relativity Space and many other amazing space startups are all within a few miles of my office in the Lloyd Greif Center for Entrepreneurial studies. Our University, the University of Southern California has long been a national leader in space research and education. Our notable space alumni include recent NASA administrator Charlie Bolden, former House Space Subcommittee Chair Dana Rohrabacher and Apollo 11 Commander Neil Armstrong. The first moonwalker actually completed his mission while enrolled at USC as master’s student in Aerospace engineering.

Former NASA Administrator, Astronaut and USC Alumni, General Charles Bolden and the author (Autry) … [+] hold up the USC “Fight On” sign at SoCal Commercial Spaceflight Initiative Conference.

Copyright: Greg Autry

Now-a-days, the commercial space industry is advancing so rapidly that even new graduates find themselves lagging behind recent real-world advances. University programs in all fields have become increasingly theory-heavy in recent years, leaving far too much practical education to industry. USC ‘s Viterbi School of Engineering has responded to this by encouraging the formation of student organizations that put hardware into the hands of students and provide learning experiences that close the gap between academia and industry. Notably, our school has two serious rocketry groups and an off-campus research center dedicated to practical spaceflight applications.

Astronautical Engineering at the University of Southern California (USC)

Just a couple decades ago, if you asked a group of engineering students, “How many of you are earning a degree in Astronautical Engineering (ASTE)?” nobody would have responded, “I am!” The study of astronautics has been embedded within the aerospace engineering program at most US universities. The two fields are related; however, they carry just as many differences as they do similarities. Most notably while aeronautics is all about managing and utilizing air flow, the complete lack of atmosphere is a primary consideration in astronautics.

USC Viterbi School of Engineering established a separate ASTE department in 2004 and the program now has over 75 undergrad and graduate students on-campus, and over 200 off-campus. ASTE’s mission is to provide students with a core understanding of space technologies by covering topics from orbital mechanics to spacecraft propulsion. “It is one of the largest pure space engineering educational programs in the country, contributing to the vital for national security and technological competitiveness industry,” says Mike Gruntman who had served the founding chairman of the new department.

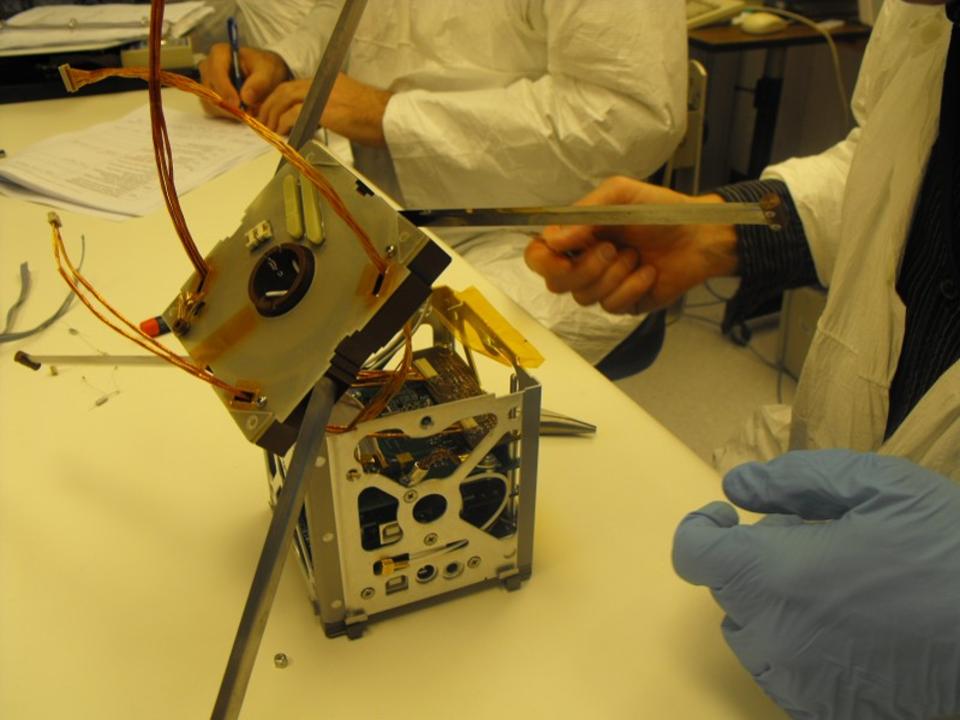

USC’s first satellite, CAERUS, built at SERC provided comms for 3U integrated mission.

SERC

USC’s Space Engineering Research Center (SERC) was founded in 2007 as a research discipline center. The SERC emphasizes hands-on space applications through a unique model that envisions an “engineering teaching hospital.” It has a broad mandate to explore innovations in space systems technology, rendezvous and proximity systems, and design/build/launch of satellites through advanced innovation. The Center has for a vibrant research portfolio from building multiple CubeSats and nanosatellites through development of a lunar lander prototype vehicle, and biologically inspired robotic grippers for servicing applications.

RPL Student Engineers prepare Traveler IV for its launch to space.

USC RPL

As the ASTE program grew, its leadership encouraged extra-curricular opportunities for additional hands-on activities for students. The Rocket Propulsion Laboratory (USC RPL) was the first undergraduate group aimed at teaching students to build and fly solid propellant rockets. The lab’s founding goal was to design, develop, and fly a solid propellant rocket that would reach space. This objective was achieved in 2019 when Traveler IVflew past the Karman line, the internationally recognized demarcation point of space at approximantly 100 kilometers. RPL members have gone onto notable careers with SpaceX, Blue Origin, and Relativity Space (a SoCal rocket company startup founded by RPL alumni Tim Ellis and Jordan Noone).

Enter, the Liquid Propulsion Laboratory

The LPL team at a test fire in the nearby Mojave Desert.

LPL

While flying solid rockets is serious work, most of today’s advanced launch systems, including SpaceX’s exciting reusable rockets, have complex engines burning liquid or liquified fuels with cryogenic oxidizers. USC’s Liquid Propulsion Laboratory (LPL) was founded in 2015 to provide student’s the opportunity to develop test at these advanced propulsion systems. The laboratory provides graduate students and some undergrads with experience developing liquid-fueled rocket engines, feed systems and ignition systems.

A graduate focused lab comes with some inherent issues; Rapid turnover rates, an extremely steep learning curve, limited experience and minimal guidance are some of the obstacles constantly in play. LPL’s early work focused on the development of training tools that advanced engine research in ways industry was headed. This work established a vibrant alumni network that helps support the lab’s continuation.

Over the past five years, LPL has static-fired four different designs of liquid-fueled engines, built four test stands, and Its membership has grown eightfold during this period. The lab has made major strides in the field of additive manufacturing. SERC Director, Dave Barnhart notes that “LPL was the first student group to build and fire a 3D printed engine and have presented papers on their research at the International Astronautical Congress in Bremen Germany last year.” LPL’s advisor, Dr. Dan Erwin, adds, “They have come up to the state of the art in 3D-printed rocket engines in a very short time and are poised to push the field due to their rapid development cycle and professional approach.”

In the first year the lab machined a relatively simple Nitrous Oxide/Kerosene engine that produced just 139.5 lbf (620 Newtons) of thrust. Today the LPL “workhorse” engines Jessie & James (J&J) are far more powerful. These second generation engines provide demonstrate additive manufacturing (AM) techniques applied to complex injector geometries. J&J were both printed out of maraging steel, a strong and ductile alloy, using a direct metal laser sintering (DMLS) process at USC’s Center for Advanced Manufacturing (CAM). With the lab’s home-built Hydra Test Stand an example of the current capabilities the groups engines can run at include:

Thrust: 747 lbf (3.32 kN)

Chamber Pressure: 1000 psi (6,895 kPa)

Chamber Temperature: 5,417 °F (3,265 K)

Propellants: Gaseous Oxygen / Kerosene

Building upon the design of J&J, the Liquid Propulsion Laboratory is currently developing a larger next generation engine named Balerion. Balerion is designed to operate at:

Thrust: 2,250 lbf (10 kN)

Chamber Pressure: 375 psi (2,585 kPa)

Chamber Temperature: 4,202 °F (2,590 K)

Propellants: Liquid Oxygen / Jet-A

LPL’s 3D printed Balerion engine.

LPL

Balerion was tested last year in the Mojave Desert, using the University of California, San Diego’s Colossus Test Stand. Even though Balerion operated well, the value of testing (and experience students gain by doing this type of work) was experienced through a newsworthy flare-up. Balerion was a 3D printed engine from Inconel-718, utilized regenerative cooling rather than ablative cooling, and features a 3D-printed pintle injector instead of a showerhead injector. The new engine was printed in two halves, another new challenge the group overcame. Moreover, the addition of 150 rectangular cooling channels no larger than 1mm in either cross-sectional dimension introduced a host of new printing considerations. Some small manufacturing defects highlighted limits of the EOS M290 printers used. Outside of engine development, LPL also use their Prometheus Test Stand (a sub-scale version of Hydra) to test thrusters and torch igniters off-campus, and a larger Water Flow Test Stand (WFTS) on campus used for conducting research on individual engine components and performing flow characterization.

Thrusting into the Future

LPL’s leadership intends to continue researching engine design on the Hydra Test Stand and run various modifications on the J&J engines as well as designing and fabricating a cryogenic capable test stand. They are also actively seeking corporate sponsorships to support the production and firing of a 2nd Balerion engine. Getting their engines into the air and eventually into space will involve cooperating with the Rocket Propulsion Laboratory Team. RPL’s proven vehicle development process, avionics systems and launch experience will eliminate work and reduce risk in building a full rocket. It is the hope of both laboratories that such a vehicle will cross the Von Karman line and allow USC to claim the distinction of first university in the world to reach space with a liquid-fueled rocket, and hopefully a re-flyable one. Barnhart remarks, “This is exactly the type of advanced research USC is known for and we are very proud of this unique student organization.” To paraphrase our favorite slogan at USC, “Flight On!”

The author would like to acknowledge the significant contributions of USC LPL team members Ryan Horton and Ulubilge Ulusoy in the production of this piece.